Automation Innovations in Next-Gen Machine Tools

The manufacturing sector is experiencing a transformative era, with automation at the forefront of its evolutionary journey. As market demands grow and competition heightens, manufacturers are increasingly seeking advanced solutions to enhance productivity, precision, and efficiency. Automation innovations in next-generation machine tools are pivotal to achieving these goals. This article delves into the latest advancements in automated machine tools, illustrating how they are revamping the manufacturing landscape.

Section 1: The Rise of Automation in Manufacturing

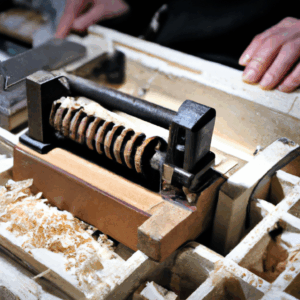

Automation has become synonymous with modern manufacturing, driven by the need to streamline operations and reduce human error. The integration of automated systems in machine tools has led to a significant reduction in production time and an increase in output quality. The adoption of technologies such as robotics, artificial intelligence (AI), and the Internet of Things (IoT) has enabled manufacturers to automate complex tasks, previously reliant on skilled human intervention.

Robotic arms, for example, are now commonplace in factories, performing repetitive tasks with speed and precision that exceed human capabilities. AI-driven analytics provide real-time insights into production processes, enabling predictive maintenance and reducing downtime. Meanwhile, IoT connectivity ensures seamless communication between machines, optimizing the entire manufacturing ecosystem.

Section 2: Smart Machine Tools and Their Impact

Smart machine tools represent the pinnacle of manufacturing automation, equipped with sensors and software that allow them to operate autonomously. These tools are capable of self-diagnosing issues and adjusting operations in real time to maintain optimal performance. The integration of machine learning algorithms enables these tools to “learn” from ongoing processes, improving efficiency and accuracy over time.

The impact of smart machine tools extends beyond efficiency. They contribute to sustainability efforts by minimizing material waste and energy consumption. Advanced data analytics allow manufacturers to monitor and control the environmental impact of their operations, aligning with global sustainability goals. By reducing manual labor, smart machine tools also help mitigate the risk of workplace injuries, creating safer working environments.

Section 3: Collaborative Robots (Cobots) in Machine Tool Automation

Collaborative robots, or cobots, are redefining the relationship between humans and machines in the manufacturing sector. Unlike traditional industrial robots, cobots are designed to work alongside human operators, enhancing productivity without replacing the human workforce. This collaboration allows for the automation of tasks that require human dexterity and decision-making alongside robotic precision.

Cobots are particularly beneficial in small to mid-sized enterprises (SMEs) that require flexible, adaptable automation solutions. Their ease of programming and deployment means they can be quickly integrated into existing production lines, providing immediate benefits. As cobots continue to evolve, they are expected to play a crucial role in automating more complex manufacturing processes.

Section 4: The Role of Artificial Intelligence in Machine Tool Automation

Artificial intelligence is a game-changer in the realm of automated machine tools. AI algorithms enable machines to process vast amounts of data, identifying patterns and making decisions that optimize production processes. Predictive analytics powered by AI can foresee potential equipment failures, allowing for proactive maintenance and avoiding costly downtime.

Moreover, AI-driven machine tools can adapt to changing production requirements on the fly, ensuring that manufacturers can meet dynamic market demands. This adaptability is crucial in industries such as automotive and aerospace, where precision and customization are paramount. By integrating AI, manufacturers can achieve faster turnaround times and higher quality products, giving them a competitive edge.

Section 5: The Future of Automation in Machine Tool Manufacturing

The future of automation in machine tools is poised for remarkable advancements, with emerging technologies such as augmented reality (AR) and digital twins gaining traction. AR can provide operators with real-time, interactive guides to streamline machine setup and maintenance. Digital twins, virtual replicas of physical assets, enable manufacturers to simulate production processes, optimizing performance and reducing costly trial-and-error.

Furthermore, advancements in 5G connectivity will enhance the communication capabilities of automated systems, allowing for faster data transfer and more responsive machine operations. As these technologies mature, the boundaries of what is possible in manufacturing automation will continue to expand, leading to even greater efficiency, innovation, and sustainability.

Conclusion

Automation innovations in next-generation machine tools are revolutionizing the manufacturing industry. By embracing technologies such as robotics, AI, and IoT, manufacturers are not only increasing efficiency and output but also enhancing safety and sustainability. As we look to the future, the continued evolution of automation promises to unlock new possibilities, driving the industry towards greater innovation and competitiveness. For manufacturing professionals, staying abreast of these advancements is crucial to harnessing their full potential and achieving long-term success.