Melody of Innovation: Future of Machine Tools Webinar

In the rapidly evolving world of manufacturing, staying ahead of the curve is not just an option but a necessity. As industries strive to enhance efficiency and productivity, the role of machine tools is becoming increasingly critical. The “Melody of Innovation: Future of Machine Tools” webinar offers a comprehensive exploration of the latest advancements and future trends in machine tool technology. This article delves into the key insights shared during the event, providing a detailed overview for manufacturing professionals looking to harness the power of innovation in their operations.

Introduction: Setting the Stage for Innovation

The manufacturing sector is experiencing a transformative phase, driven by cutting-edge technologies and innovative practices. Machine tools, the backbone of manufacturing, are evolving at a pace never seen before. This webinar brought together industry experts, engineers, and innovators to discuss the future of machine tools and their impact on manufacturing processes. From precision engineering to automation, the discussions covered a wide range of topics, setting the stage for a new era of manufacturing innovation.

Section 1: The Evolution of Machine Tools

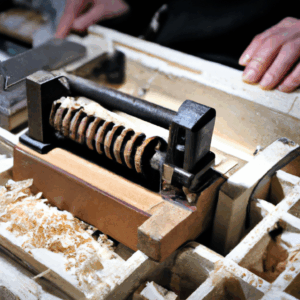

Machine tools have undergone significant transformation since their inception. Initially designed for basic metalworking tasks, they have evolved into sophisticated machines capable of performing complex operations with high precision. The webinar highlighted the historical journey of machine tools, emphasizing the technological milestones that have shaped their development. From manual controls to computer numerical control (CNC) systems, each leap forward has paved the way for greater accuracy and efficiency in manufacturing.

Key speakers discussed how CNC technology revolutionized the industry by automating machining processes, reducing human error, and increasing production speed. The integration of digital technologies and IoT in machine tools was also a focal point, illustrating how connected devices are enabling real-time data analysis and predictive maintenance, thus enhancing operational efficiency.

Section 2: Current Trends in Machine Tool Technology

Today, machine tools are at the forefront of technological advancement, incorporating innovations that were once considered science fiction. The webinar explored several current trends that are shaping the industry. One major trend is the use of additive manufacturing, which allows for the creation of complex geometries and reduces material waste. Hybrid machines that combine additive and subtractive processes were highlighted as game changers, offering unparalleled flexibility and efficiency.

Another significant trend is the move towards smart manufacturing. Machine tools equipped with sensors and connectivity features are enabling manufacturers to implement smart factories, where machines communicate and cooperate to optimize production processes. The speakers also discussed the role of artificial intelligence in enhancing machine tool capabilities, such as adaptive machining and autonomous decision-making.

Section 3: Challenges and Solutions in Machine Tool Innovation

While the advancements in machine tool technology are promising, they come with their own set of challenges. The webinar addressed some of the most pressing issues facing the industry. One major challenge is the integration of new technologies with existing systems, which requires significant investment and expertise. Additionally, the rapid pace of technological change can make it difficult for manufacturers to keep up, leading to a skills gap in the workforce.

To overcome these challenges, the speakers emphasized the importance of continuous learning and adaptation. Investing in training programs for employees and fostering a culture of innovation within organizations were suggested as effective strategies. Furthermore, collaboration between manufacturers, technology providers, and educational institutions was recommended to bridge the skills gap and drive the industry forward.

Section 4: The Future Landscape of Machine Tools

Looking ahead, the future of machine tools appears bright, with numerous opportunities for growth and innovation. The webinar painted a picture of a future where machine tools are more intelligent, autonomous, and sustainable. The concept of the “lights-out” factory, where machines operate independently without human intervention, was discussed as a potential reality, driven by advancements in AI and robotics.

Sustainability was another key theme, with speakers highlighting the role of machine tools in promoting eco-friendly manufacturing practices. Energy-efficient machines and processes that minimize waste and reduce carbon footprints are becoming increasingly important as industries strive to meet environmental regulations and consumer expectations.

Section 5: Preparing for the Future of Machine Tools

For manufacturing professionals, preparing for the future of machine tools involves a proactive approach to innovation and change. The webinar provided valuable insights into how organizations can position themselves for success in this dynamic landscape. Embracing digital transformation, investing in cutting-edge technologies, and fostering a culture of innovation were identified as critical steps.

The speakers also stressed the importance of building strong partnerships and networks within the industry. By collaborating with other manufacturers, technology providers, and research institutions, companies can gain access to new ideas, technologies, and markets. This collaborative approach not only accelerates innovation but also helps mitigate risks associated with technological change.

Conclusion: Harmonizing Innovation and Tradition

The “Melody of Innovation: Future of Machine Tools” webinar underscored the importance of harmonizing innovation with traditional manufacturing practices. As machine tools continue to evolve, they offer exciting opportunities for manufacturers to enhance productivity, accuracy, and sustainability. However, realizing this potential requires a commitment to continuous learning, collaboration, and strategic investment.

In conclusion, the future of machine tools is a symphony of technological advancements and human ingenuity. By embracing the melody of innovation, manufacturing professionals can not only stay ahead of the curve but also drive the industry towards a more prosperous and sustainable future. As we look to the horizon, it is clear that the future of machine tools holds endless possibilities, limited only by our imagination and willingness to innovate.