Future Innovation AI CNC Technology Fair

The rapid evolution of technology in the manufacturing industry is nothing short of remarkable. As we delve deeper into the 21st century, the integration of Artificial Intelligence (AI) with Computer Numerical Control (CNC) machines has opened new horizons for innovation and efficiency. The Future Innovation AI CNC Technology Fair is a pivotal event that showcases cutting-edge advancements in this space, offering insights, networking opportunities, and a glimpse into the future of manufacturing. This article explores the key highlights and innovations presented at the fair.

Section 1: The Convergence of AI and CNC Technology

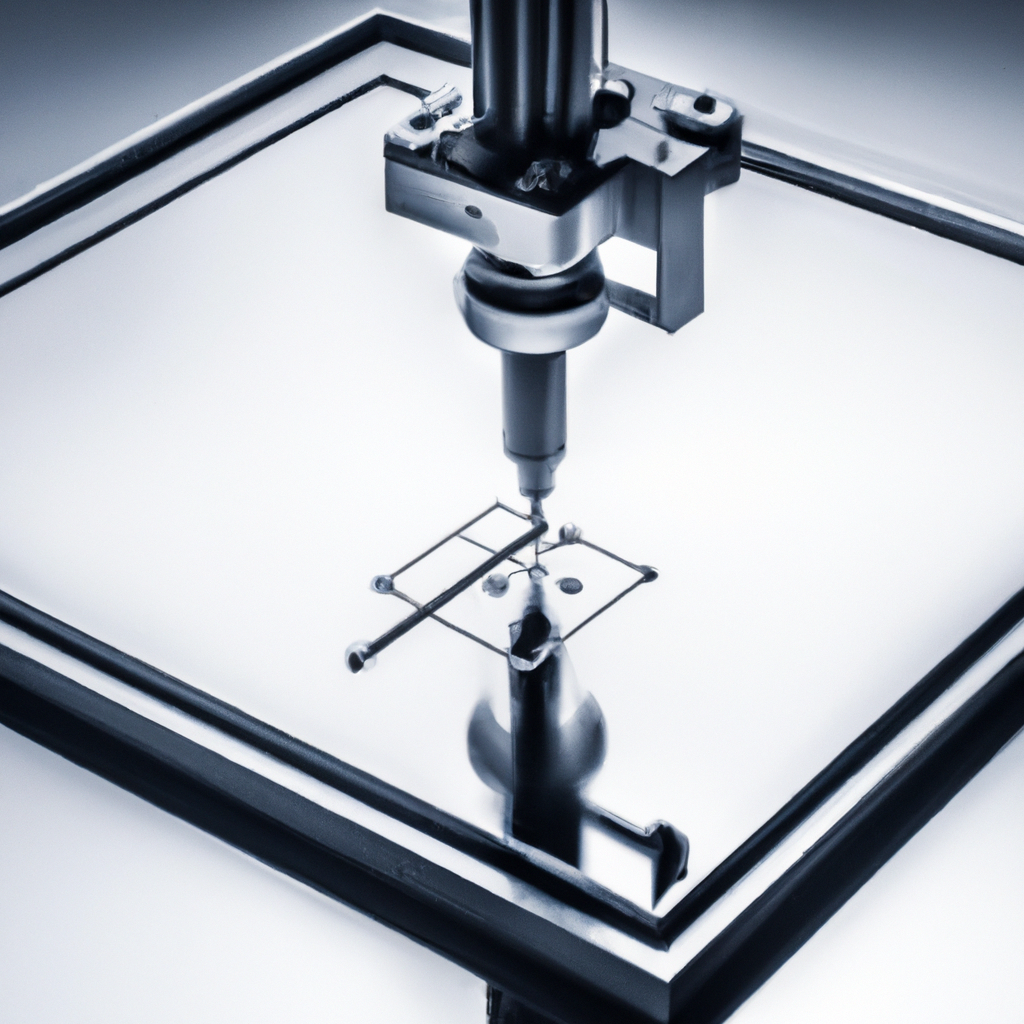

The convergence of AI and CNC technology represents a transformative shift in the manufacturing landscape. AI’s ability to process and analyze vast amounts of data enables CNC machines to operate with unprecedented precision and efficiency. At the fair, experts emphasized how AI algorithms are being deployed to optimize machining processes, reduce waste, and improve quality control. Real-time data analysis allows CNC machines to adjust operations on the fly, minimizing downtime and enhancing productivity.

One of the standout innovations discussed was predictive maintenance. By leveraging AI, manufacturers can predict when a machine is likely to fail, allowing for preemptive maintenance and reducing costly disruptions. This capability not only extends the lifespan of the machinery but also ensures a smoother production workflow.

Section 2: Smart Manufacturing and Industry 4.0

The fair highlighted the concept of smart manufacturing, a crucial component of Industry 4.0. Smart manufacturing utilizes interconnected systems that communicate in real-time, allowing for more agile and responsive production processes. AI-enhanced CNC machines play a critical role in this ecosystem by providing the flexibility and intelligence needed to adapt to dynamic manufacturing demands.

Presentations at the fair showcased how smart factories utilize AI-driven CNC machines to customize products on demand, significantly reducing lead times and enhancing customer satisfaction. Additionally, the integration of IoT devices with CNC machines facilitates seamless communication across the production line, ensuring that every component is in sync and operating at peak efficiency.

Section 3: Enhancing Precision and Customization

Precision and customization were central themes at the Future Innovation AI CNC Technology Fair. AI algorithms are now capable of interpreting complex design specifications and translating them into precise machining instructions. This capability allows manufacturers to produce highly intricate parts with minimal error, which is particularly beneficial in industries such as aerospace and medical devices where precision is paramount.

The fair also showcased advancements in customization capabilities. With AI-driven CNC machines, manufacturers can offer highly personalized products without the traditional cost penalties associated with customization. This flexibility opens new market opportunities and enhances competitive positioning by allowing companies to meet specific customer needs more effectively.

Section 4: Reducing Environmental Impact

As sustainability becomes an increasingly important consideration, the fair emphasized the role of AI and CNC technology in reducing environmental impact. AI can optimize energy consumption and material usage, leading to greener manufacturing processes. CNC machines, guided by AI, can precisely calculate the minimal material required for each part, minimizing waste and reducing the carbon footprint.

There were also discussions on how AI can aid in the development of eco-friendly materials and manufacturing techniques. By analyzing material properties and performance, AI can assist in creating more sustainable alternatives that do not compromise on quality or functionality.

Section 5: Overcoming Challenges and Driving Adoption

Despite the numerous benefits, the integration of AI into CNC technology is not without its challenges. The fair addressed common hurdles such as the high initial investment costs, the need for skilled workforce, and the integration with existing systems. Experts provided insights into overcoming these barriers by highlighting successful case studies and offering strategic guidance on technology adoption.

Workshops and panel discussions focused on training and education as key drivers for widespread adoption. As AI and CNC technology continue to evolve, upskilling the workforce becomes essential. Providing engineers and operators with the necessary training ensures they can effectively leverage new technologies, maximizing their potential and fostering innovation within their organizations.

Conclusion

The Future Innovation AI CNC Technology Fair provided a comprehensive overview of the transformative impact of AI on CNC technology. As manufacturers continue to navigate the complexities of modern production, the integration of AI offers a pathway to greater efficiency, precision, and sustainability. By embracing these advancements, the manufacturing industry can not only enhance its operational capabilities but also contribute to a more sustainable and innovative future. The insights and innovations showcased at the fair serve as a testament to the potential of AI-driven CNC technology in shaping the next era of manufacturing excellence.