Future-Driven Machine Tool Automation Expo

The manufacturing industry is on the cusp of a new era, driven by rapid advancements in automation and smart technologies. The “Future-Driven Machine Tool Automation Expo” is a pivotal event for professionals eager to explore the cutting-edge innovations reshaping the manufacturing landscape. This article delves into the key themes and takeaways from the expo, highlighting the transformative potential of automation in machine tools.

Introduction

The integration of automation within machine tools is not just an incremental step but a leap towards smarter manufacturing processes. As industries across the globe strive to enhance efficiency, reduce costs, and improve product quality, the role of automation becomes increasingly crucial. The Future-Driven Machine Tool Automation Expo serves as a platform for industry leaders, engineers, and innovators to showcase and discuss the latest advancements in this field. Attendees gain insights into how these technologies can be harnessed to meet current and future manufacturing challenges.

1. The Evolution of Machine Tool Automation

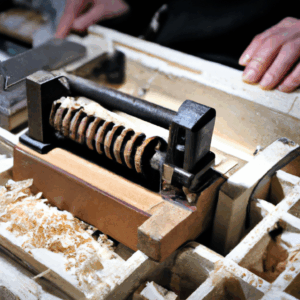

Automation in machine tools has come a long way from its early beginnings. Initially, automation was limited to simple repetitive tasks, but it has since evolved into sophisticated systems capable of complex operations. This section of the expo examined the historical milestones that have defined machine tool automation and the technological breakthroughs that have propelled it forward.

From the advent of CNC (Computer Numerical Control) machines to the integration of AI (Artificial Intelligence) and IoT (Internet of Things), automation technologies have continuously advanced. These innovations have not only improved the accuracy and speed of machining processes but have also enabled the development of fully automated production lines that require minimal human intervention.

2. Key Innovations in Automation Technology

The expo highlighted several key innovations that are set to revolutionize machine tool automation. One of the standout technologies is the use of AI-driven predictive maintenance systems. These systems utilize machine learning algorithms to predict potential equipment failures before they occur, thereby minimizing downtime and maintenance costs.

Another significant innovation is the integration of IoT devices, which allows for seamless communication between machines and central control systems. This connectivity facilitates real-time monitoring and data analysis, enabling manufacturers to optimize their operations and respond quickly to changes in demand.

Additionally, advancements in robotics have made it possible to automate tasks that were previously deemed too complex for machines. Collaborative robots, or cobots, are designed to work alongside human operators, enhancing productivity and ensuring safety in the workplace.

3. The Impact of Automation on Manufacturing Efficiency

Automation is a key driver of efficiency in manufacturing. By automating repetitive and labor-intensive tasks, manufacturers can significantly reduce cycle times and increase production rates. The expo showcased numerous case studies demonstrating how companies have successfully implemented automation to streamline their operations.

For instance, the adoption of automated assembly lines has enabled manufacturers to scale up production without a proportional increase in labor costs. Furthermore, automation reduces the likelihood of human error, ensuring consistent product quality and reducing waste.

In addition to improving efficiency, automation also enhances flexibility in manufacturing. With automated systems, manufacturers can quickly reconfigure production lines to accommodate new product designs or changes in customer demand, providing a competitive edge in today’s fast-paced market.

4. Challenges and Considerations in Implementing Automation

While the benefits of automation are clear, implementing these technologies is not without challenges. The expo addressed several common obstacles that manufacturers face when integrating automation into their operations.

One of the primary challenges is the initial cost of investment. High-quality automated systems can be expensive, and businesses must carefully evaluate the return on investment before proceeding. Additionally, there is a need for skilled personnel to manage and maintain these systems, which can be a barrier for some companies.

Another consideration is the potential impact on the workforce. As machines take over tasks traditionally performed by humans, there is a concern about job displacement. However, many experts at the expo emphasized that automation creates new opportunities for skilled workers, as it requires expertise in programming, maintenance, and system optimization.

5. The Future of Machine Tool Automation

The future of machine tool automation is bright, with endless possibilities for innovation and growth. The expo provided a glimpse into the future, showcasing emerging technologies that promise to further enhance manufacturing processes.

One area of interest is the development of fully autonomous factories, where machines handle every aspect of production from start to finish. These smart factories leverage AI and IoT to operate with minimal human intervention, offering unprecedented levels of efficiency and precision.

Furthermore, advancements in additive manufacturing, or 3D printing, are set to complement traditional machining processes. This technology allows for the creation of complex parts with minimal waste, and when combined with automation, it can revolutionize product development and customization.

Conclusion

The Future-Driven Machine Tool Automation Expo underscored the transformative impact of automation on the manufacturing industry. As technologies continue to evolve, manufacturers must stay abreast of these changes to remain competitive in a rapidly changing market. By embracing automation, businesses can unlock new levels of efficiency, flexibility, and innovation, paving the way for a more advanced and sustainable manufacturing future.

In conclusion, the expo not only highlighted the latest advancements in machine tool automation but also provided valuable insights into the strategic implementation of these technologies. For manufacturing professionals, the event was an invaluable opportunity to network with industry leaders, explore new technologies, and envision the future of manufacturing.