Future of Manufacturing: Machine Tool Automation Seminar

The manufacturing landscape is undergoing a transformative shift driven by advancements in machine tool automation. As industries strive to increase efficiency, reduce costs, and improve product quality, the role of automation in manufacturing becomes increasingly pivotal. This article delves into the insights and discussions from a recent seminar focused on the future of machine tool automation, highlighting key trends, technologies, and strategies that are shaping the future of manufacturing.

1. The Evolution of Machine Tool Automation

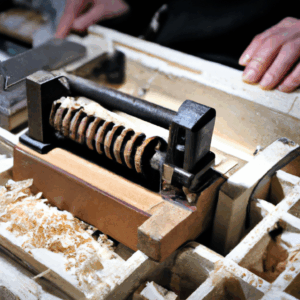

Machine tool automation has evolved significantly over the past few decades. Initially, automation in manufacturing was limited to simple mechanization for repetitive tasks. However, with the advent of computer numerical control (CNC) and robotics, automation has become more sophisticated. Today, machine tool automation encompasses a range of technologies including advanced robotics, artificial intelligence (AI), and the Internet of Things (IoT), which work together to create smart manufacturing environments.

During the seminar, industry experts discussed how these technologies have enabled manufacturers to achieve unprecedented levels of precision and efficiency. The integration of AI and machine learning in automation systems allows for predictive maintenance, reducing downtime and improving the overall productivity of manufacturing systems.

2. Key Technologies Driving Automation

The seminar highlighted several key technologies that are driving the current wave of machine tool automation:

- Robotics: The use of robotic systems in manufacturing has expanded beyond traditional assembly line tasks. Advanced robots now play roles in material handling, quality inspection, and even collaborative tasks alongside human workers.

- AI and Machine Learning: These technologies are essential for developing smart manufacturing systems capable of self-optimization. AI algorithms analyze data from various sensors and make real-time adjustments to improve efficiency and product quality.

- IoT and Connectivity: The IoT connects machines, tools, and devices, enabling seamless data exchange and system integration. This connectivity allows for better monitoring and control of manufacturing processes.

- 3D Printing: Additive manufacturing is revolutionizing prototyping and production processes, allowing for more complex and customized parts to be manufactured with ease.

These technologies are not only enhancing the capabilities of existing manufacturing systems but are also paving the way for entirely new manufacturing paradigms.

3. Challenges and Solutions in Implementing Automation

While the benefits of machine tool automation are clear, implementing these technologies comes with its own set of challenges. One of the primary concerns discussed during the seminar was the high initial investment required for automation technologies. However, industry leaders emphasized that the long-term savings and productivity gains often justify the upfront costs.

Another challenge is the integration of new technologies with existing systems. Legacy equipment and infrastructure can make it difficult to achieve seamless automation. Solutions discussed included gradual integration strategies and the use of modular automation systems that can be scaled and adapted over time.

The seminar also addressed the skills gap in the workforce. As automation technologies advance, there is a growing need for workers who are skilled in operating and maintaining these systems. Training and education programs were highlighted as essential for preparing the workforce for the future of manufacturing.

4. Case Studies: Successful Automation Implementation

The seminar featured several case studies showcasing successful implementations of machine tool automation. These real-world examples provided valuable insights into the practical applications and benefits of automation technologies:

- Automotive Industry: A leading automotive manufacturer shared their experience with integrating robotics and AI into their production lines, resulting in a 30% increase in production efficiency and a significant reduction in defects.

- Aerospace Manufacturing: An aerospace company discussed their use of IoT-enabled systems for real-time monitoring of production processes, leading to improved quality control and reduced waste.

- Consumer Electronics: A consumer electronics firm highlighted their use of 3D printing for rapid prototyping, which has shortened product development cycles and allowed for more innovative designs.

These case studies illustrate the tangible benefits that can be achieved through strategic automation initiatives and serve as inspiration for other manufacturers looking to adopt similar technologies.

5. The Future of Machine Tool Automation

Looking to the future, the seminar explored several trends and predictions for machine tool automation. One of the key trends is the increasing use of cloud-based platforms for manufacturing operations. These platforms enable manufacturers to access powerful computing resources and data analytics tools without the need for extensive on-site infrastructure.

Another anticipated development is the rise of collaborative robots, or cobots, which are designed to work alongside human operators. Cobots are expected to become more prevalent as they offer flexibility and can be easily integrated into existing workflows.

Additionally, the concept of digital twins—virtual replicas of physical systems—was discussed as a way to simulate and optimize manufacturing processes in a digital environment before implementing changes on the shop floor.

Conclusion

The seminar on machine tool automation provided a comprehensive overview of the current state and future prospects of automation in manufacturing. As technologies continue to evolve, manufacturers have the opportunity to leverage automation to enhance productivity, reduce costs, and improve product quality. By addressing the challenges and embracing the opportunities presented by machine tool automation, manufacturers can position themselves at the forefront of the industry, ready to meet the demands of the future.

The future of manufacturing is undoubtedly exciting, with automation playing a crucial role in shaping its trajectory. As more manufacturers adopt these technologies, the industry will continue to evolve, driving innovation and growth across the global economy.