Shaping the Future: Automation Innovation in Machine Tools Seminar

The manufacturing industry stands on the brink of a transformative era, driven by the rapid advancement of automation technologies. As we venture further into the 21st century, the integration of automated systems in machine tools presents unprecedented opportunities for efficiency, precision, and innovation. This article explores the key insights and discussions from the “Shaping the Future: Automation Innovation in Machine Tools Seminar,” a pivotal event for manufacturing professionals aiming to stay ahead in the competitive landscape.

Introduction to Automation in Machine Tools

Automation in machine tools is not just a trend; it is a necessity for manufacturers looking to enhance productivity and maintain a competitive edge. The seminar emphasized the profound impact of automation on various aspects of manufacturing, including cost reduction, quality improvement, and the ability to meet increasing demands with agility. By integrating smart technologies, manufacturers can unlock new levels of efficiency and productivity.

Section 1: The Evolution of Automation Technologies

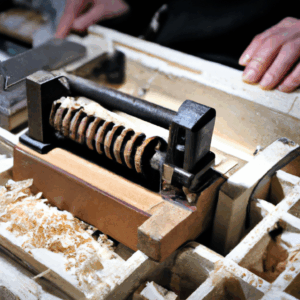

The seminar commenced with a comprehensive overview of the evolution of automation technologies in machine tools. From the advent of computer numerical control (CNC) systems to the latest advancements in artificial intelligence (AI) and the Internet of Things (IoT), the journey of automation has been remarkable. Speakers highlighted how these technologies have transformed traditional manufacturing processes, enabling machines to operate with minimal human intervention while maximizing output and precision.

Industry pioneers shared insights into the development of autonomous machining systems, which are now capable of self-monitoring and self-adjusting to optimize performance. These advancements have paved the way for smart factories, where interconnected machines communicate seamlessly to streamline operations.

Section 2: Benefits of Automation in Machine Tools

The benefits of automation in machine tools were a focal point of the seminar, with experts discussing how these innovations lead to significant advantages for manufacturers. Automation enhances operational efficiency by reducing cycle times and minimizing errors, resulting in higher quality products and reduced waste. Additionally, automated systems enable flexible manufacturing, allowing for quick adaptation to changes in product design and production volume.

Another critical benefit discussed was the improved safety in manufacturing environments. By automating dangerous or repetitive tasks, manufacturers can protect their workforce from potential hazards, leading to a safer workplace and reduced downtime due to accidents.

Section 3: Challenges and Solutions in Implementing Automation

While the advantages of automation are clear, the seminar also addressed the challenges that manufacturers face in implementing these technologies. One major challenge is the initial investment required for automation infrastructure, which can be substantial. However, speakers highlighted solutions such as phased implementation and government incentives that can alleviate financial burdens.

Another challenge is the need for skilled personnel to manage and maintain automated systems. The seminar underscored the importance of workforce training and development to ensure that employees are equipped with the necessary skills to operate and troubleshoot advanced machinery. Collaboration with educational institutions and the creation of specialized training programs were proposed as effective strategies to bridge the skills gap.

Section 4: Case Studies of Successful Automation Implementation

Real-world examples of successful automation implementation provided attendees with valuable insights into best practices and strategies. The seminar featured case studies from leading companies that have embraced automation to drive growth and innovation. These companies demonstrated how automation has enabled them to achieve remarkable results, such as doubling production capacity, enhancing product quality, and reducing operational costs.

By sharing their experiences, these companies offered practical guidance on overcoming common implementation hurdles and maximizing the benefits of automation. Their stories served as inspiration for other manufacturers looking to embark on their automation journey.

Section 5: The Future of Automation in Machine Tools

The seminar concluded with a forward-looking discussion on the future of automation in machine tools. Experts predicted that the next wave of innovation will be driven by advancements in AI and machine learning, which will further enhance the capabilities of automated systems. The integration of IoT and data analytics will enable predictive maintenance, ensuring that machines operate at optimal efficiency and reducing unplanned downtime.

Furthermore, the rise of collaborative robots, or cobots, is expected to revolutionize the way humans and machines work together. These robots are designed to work alongside human operators, combining the precision of automation with the adaptability of human intelligence.

Conclusion: Embracing the Future of Manufacturing

The “Shaping the Future: Automation Innovation in Machine Tools Seminar” provided a comprehensive overview of the opportunities and challenges that come with integrating automation into manufacturing processes. As the industry moves towards a more automated future, it is essential for manufacturers to embrace these innovations to remain competitive. By investing in automation technologies, developing a skilled workforce, and learning from successful implementations, manufacturers can shape a future that is not only efficient and productive but also innovative and sustainable.

Automation in machine tools is not merely about replacing human labor; it is about enhancing human capability and creating new possibilities for growth. As we look to the future, the potential of automation is limitless, and those who embrace it will lead the way in shaping the manufacturing landscape of tomorrow.