Future of Meta-Manufacturing Expo

The manufacturing industry stands on the brink of a transformative era characterized by the integration of advanced technologies and innovative practices. As we look towards the future, the concept of meta-manufacturing emerges as a pivotal force in redefining production processes and supply chain efficiencies. The Future of Meta-Manufacturing Expo serves as a platform for industry leaders, innovators, and professionals to explore these groundbreaking developments. This article delves into the core themes of the expo, highlighting key areas of focus and the potential impacts on the manufacturing landscape.

Section 1: Understanding Meta-Manufacturing

Meta-manufacturing refers to the holistic integration of digital technologies, advanced materials, and intelligent systems within the manufacturing process. Unlike traditional manufacturing, which often relies on linear processes, meta-manufacturing embraces a more interconnected approach. By leveraging digital twins, IoT, AI, and machine learning, manufacturers can create a seamless and adaptive production environment.

This approach facilitates real-time data analytics, predictive maintenance, and enhanced decision-making capabilities. At the expo, attendees will have the opportunity to explore how these technologies are being utilized to optimize operations, reduce waste, and improve product quality.

Section 2: The Role of Digital Twins and IoT

Digital twins and the Internet of Things (IoT) are critical components of meta-manufacturing. A digital twin is a virtual replica of a physical asset, process, or system, enabling manufacturers to simulate and analyze performance under various conditions. This technology allows for predictive maintenance, reducing downtime and extending the lifespan of equipment.

IoT further enhances this capability by connecting machines, sensors, and devices across the manufacturing floor. The data collected through IoT devices can be analyzed to provide insights into production efficiency and potential bottlenecks. At the expo, experts will showcase how the integration of digital twins and IoT can lead to smarter manufacturing processes and improved resource management.

Section 3: Advanced Materials and Additive Manufacturing

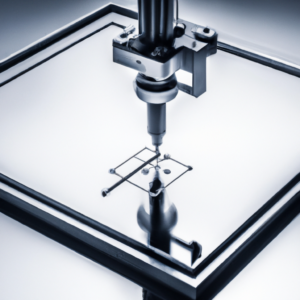

The development and application of advanced materials are integral to the future of manufacturing. Innovations in materials science have given rise to stronger, lighter, and more sustainable alternatives that can revolutionize product design and functionality. Additive manufacturing, commonly known as 3D printing, plays a crucial role in this transformation.

Additive manufacturing allows for the creation of complex geometries and customized components that are not feasible with traditional methods. During the expo, industry leaders will discuss the latest advancements in material science and how additive manufacturing is being used to produce high-performance parts with reduced material waste and energy consumption.

Section 4: AI-Driven Automation and Robotics

Artificial Intelligence (AI) and robotics are reshaping the manufacturing landscape by enabling greater automation and precision. AI-driven systems can analyze vast amounts of data to optimize production schedules, enhance quality control, and predict equipment failures before they occur. This level of automation reduces human error and increases overall efficiency.

Robotics, on the other hand, is transforming the physical aspects of manufacturing. From assembly lines to warehouse logistics, robots are being deployed to perform tasks that are repetitive, dangerous, or require high precision. The expo will feature demonstrations of the latest AI and robotic technologies, showcasing their applications in smart factories and collaborative human-robot environments.

Section 5: Sustainability and Circular Economy

As environmental concerns continue to rise, sustainability has become a central focus in manufacturing. Meta-manufacturing aligns closely with the principles of the circular economy, which emphasizes resource efficiency and waste reduction. By adopting sustainable practices, manufacturers can minimize their environmental footprint while also reducing costs.

The expo will highlight innovations in sustainable manufacturing, such as the use of renewable energy, recycling of materials, and the development of eco-friendly products. Discussions will also focus on how digital technologies can support sustainability goals by optimizing resource usage and enabling more efficient supply chain management.

Conclusion: Embracing the Future of Manufacturing

The Future of Meta-Manufacturing Expo offers a glimpse into the transformative potential of advanced technologies and innovative practices in the manufacturing sector. By embracing meta-manufacturing, companies can achieve greater efficiency, sustainability, and competitiveness in a rapidly changing global market. As industry professionals gather to share insights and explore new possibilities, the expo serves as a catalyst for collaboration and innovation, paving the way for a more resilient and dynamic manufacturing industry.

As we move forward, it is essential for manufacturers to stay informed and adaptable, leveraging the advancements showcased at the expo to drive their future success. By doing so, they can not only meet the challenges of today but also seize the opportunities of tomorrow.