Revolutionizing the Future with Machine Tools

The manufacturing industry stands on the brink of a transformative era, driven by the evolution of machine tools. These indispensable instruments are not only enhancing productivity but also redefining the possibilities within manufacturing processes. As we delve deeper into the digital age, machine tools are becoming smarter, more efficient, and increasingly pivotal in shaping the future of manufacturing.

1. The Evolution of Machine Tools: A Historical Perspective

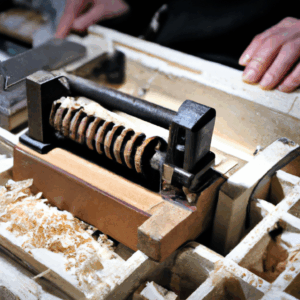

Machine tools have been fundamental to manufacturing since the industrial revolution. From the steam-powered lathes and milling machines of the 18th century to the electrically powered and CNC (Computer Numerical Control) machines of the late 20th century, each advancement has set the stage for increased precision and productivity. Today, machine tools are at the forefront of technological innovation, incorporating advanced materials, automation, and digital technologies.

Historically, the development of machine tools mirrored the technological capabilities of their time. Early machines were limited by the materials and mechanical knowledge available, but they laid the groundwork for the sophisticated systems we see today. With the advent of electricity and electronics, machine tools evolved rapidly, enabling the mass production of goods and shaping the industrial landscape of the 20th century.

2. The Integration of Digital Technology

In the current era, the integration of digital technology into machine tools is revolutionizing manufacturing processes. CNC machines are a prime example, offering unprecedented control over machining operations. By utilizing computer programs, CNC machines can execute complex tasks with high precision and repeatability, reducing human error and enhancing efficiency.

Beyond CNC, the rise of IoT (Internet of Things) and Industry 4.0 is further transforming machine tools. These technologies enable machines to communicate with each other and with central systems, allowing for real-time data collection and analysis. This connectivity facilitates predictive maintenance, reduces downtime, and enhances the overall efficiency of manufacturing operations.

3. Advanced Materials and Manufacturing Techniques

The capabilities of machine tools have expanded significantly with the use of advanced materials and manufacturing techniques. High-performance materials such as composites, ceramics, and advanced alloys require sophisticated machining processes that modern machine tools can provide. These materials are crucial for industries like aerospace, automotive, and medical technology, where durability, weight reduction, and precision are paramount.

Moreover, additive manufacturing, or 3D printing, is increasingly integrated with traditional machine tools to create hybrid manufacturing systems. These systems leverage the strengths of both subtractive and additive processes, enabling the production of complex geometries that were previously unattainable. This synergy is opening new avenues for customization and innovation in product design.

4. Automation and Robotics in Machine Tools

The incorporation of automation and robotics in machine tools is another significant trend reshaping the manufacturing landscape. Automated systems enhance productivity by performing repetitive tasks with high accuracy and speed. Robotics, when integrated with machine tools, can handle materials, perform quality inspections, and even conduct repairs, reducing the necessity for human intervention.

Additionally, the use of collaborative robots, or cobots, is on the rise. These robots work alongside human operators, combining the strengths of human skill and robotic precision. Cobots are particularly useful in flexible manufacturing environments where human expertise is essential for complex decision-making, while robots handle the execution of tasks.

5. The Future of Machine Tools: Challenges and Opportunities

As machine tools continue to evolve, they present both challenges and opportunities for the manufacturing industry. On one hand, the rapid pace of technological advancement requires significant investment in new equipment and training for the workforce. Manufacturers must stay abreast of emerging technologies and continuously upgrade their capabilities to remain competitive.

On the other hand, the opportunities are vast. Machine tools are integral to the advancement of smart factories and the broader digital transformation of manufacturing. They enable the production of high-quality, customized products at scale, meeting the demands of an increasingly discerning global market. Furthermore, by embracing sustainable practices and energy-efficient technologies, machine tools can contribute to reducing the environmental footprint of manufacturing activities.

Conclusion

The revolution of machine tools is at the heart of the ongoing transformation in manufacturing. By embracing digital technologies, advanced materials, automation, and sustainability, machine tools are not only increasing the efficiency and capabilities of manufacturing processes but also shaping the future of industries worldwide. As we look forward, the continuous innovation within this field will undoubtedly unlock new potentials and redefine the limits of what is possible in manufacturing.

For manufacturing professionals, staying informed and adaptable is crucial. By leveraging the latest advancements in machine tools, manufacturers can not only enhance their operations but also contribute to the broader goal of a more efficient, sustainable, and innovative industrial future.