Seminar on Future-Driven Machine Tools

In today’s rapidly evolving manufacturing landscape, staying ahead of the curve is not just an advantage—it’s a necessity. Machine tools, the backbone of manufacturing processes, are evolving with cutting-edge technologies to meet the demands of the future. Recently, a seminar titled “Future-Driven Machine Tools” brought together industry experts, engineers, and manufacturing professionals to explore the innovations and trends shaping the future of machine tools. This seminar provided invaluable insights into how machine tools are adapting to the needs of modern manufacturing, enhancing productivity, and ensuring sustainability.

1. The Role of Automation in Machine Tools

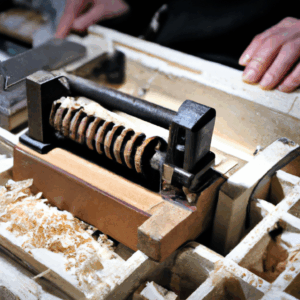

Automation has become a cornerstone in modern manufacturing, driving efficiency and precision. The seminar highlighted how automation is integrating with machine tools to reduce human intervention and increase operational efficiency. Today’s machine tools are equipped with advanced sensors, IoT connectivity, and AI-driven software that enable real-time monitoring and decision-making. These technologies allow for predictive maintenance, minimizing downtime, and optimizing the production process.

For instance, CNC machines are now capable of self-correcting minor errors during machining, thanks to sophisticated algorithms and machine learning capabilities. This not only enhances the quality of the final product but also significantly reduces waste, aligning with sustainable manufacturing goals.

2. The Impact of Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, is revolutionizing the way components are designed and produced. The seminar shed light on how this technology is complementing traditional subtractive manufacturing methods. Machine tools are now being developed to incorporate additive manufacturing capabilities, allowing for hybrid processing. This integration opens up new possibilities in design complexity and material usage.

The ability to produce complex geometries that were previously impossible with traditional methods is a game-changer. Moreover, additive manufacturing supports rapid prototyping, enabling faster iteration cycles and reducing time-to-market. As a result, manufacturers can respond quickly to market demands and customize products with greater flexibility.

3. Advancements in Material Science

Material science is another critical area that is influencing the future of machine tools. The seminar emphasized how new materials and composites are being developed to enhance the performance of machine tools. Lightweight yet strong materials are increasingly being used to improve the speed and efficiency of machining processes.

In addition, there is a growing focus on sustainability, with the development of eco-friendly materials that reduce the environmental impact of manufacturing. The use of recycled and bio-based materials is becoming more prevalent, aligning with the global push towards greener manufacturing practices. These advancements in material science not only improve the capabilities of machine tools but also contribute to the overall sustainability of the manufacturing industry.

4. The Shift Towards Smart Manufacturing

The concept of smart manufacturing is transforming the way machine tools are utilized. The seminar discussed how Industry 4.0 technologies, such as the Internet of Things (IoT), big data analytics, and cloud computing, are being integrated into machine tools to create smart factories. These technologies enable seamless communication between machines, systems, and operators, facilitating a more connected and efficient manufacturing environment.

Smart machine tools can autonomously adjust parameters, predict potential issues before they arise, and optimize production schedules in real-time. This level of intelligence not only enhances productivity but also ensures a higher level of quality control. As manufacturers continue to adopt smart manufacturing principles, machine tools will play a pivotal role in achieving operational excellence.

5. Sustainability and Energy Efficiency

Sustainability is no longer an option but a requirement in today’s manufacturing sector. The seminar highlighted the importance of developing machine tools that are energy-efficient and environmentally friendly. Advances in technology are enabling the creation of machine tools that consume less power and produce minimal waste.

Energy-efficient motors, regenerative braking systems, and advanced cooling technologies are just a few examples of how machine tools are becoming more sustainable. Additionally, the use of renewable energy sources to power manufacturing facilities is gaining traction. By reducing the carbon footprint of machine tools, manufacturers can contribute to global efforts to combat climate change while also reducing operational costs.

Conclusion

The “Future-Driven Machine Tools” seminar provided a comprehensive overview of the trends and technologies that are shaping the future of the manufacturing industry. As automation, additive manufacturing, material science, smart manufacturing, and sustainability continue to evolve, machine tools are poised to become more advanced and efficient.

For manufacturing professionals, staying informed about these developments is crucial to maintaining a competitive edge. By embracing these innovations, manufacturers can enhance productivity, improve product quality, and contribute to a more sustainable future. The insights shared at the seminar underscore the importance of continuous learning and adaptation in the ever-changing world of manufacturing.