Shaping the Future: The Automation Revolution in Machine Tools

The world of manufacturing is undergoing a significant transformation. As industries strive for greater efficiency and productivity, the automation of machine tools has emerged as a pivotal force shaping the future. This automation revolution is not only enhancing precision and speed but also redefining the capabilities and roles of machine tools in modern manufacturing. In this article, we delve into the critical aspects of this transformation, exploring how automation is revolutionizing machine tools and what it means for the future of manufacturing.

1. The Evolution of Machine Tool Automation

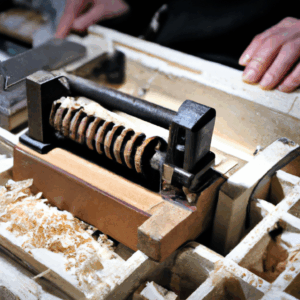

The journey of machine tool automation is a testament to human ingenuity and the relentless pursuit of excellence. Historically, machine tools have evolved from simple, manually operated devices to sophisticated automated systems capable of executing complex tasks with minimal human intervention. The introduction of Computer Numerical Control (CNC) in the late 20th century marked a significant milestone, enabling machines to follow precise digital instructions and significantly reducing the need for manual input.

Today, the evolution continues with the integration of advanced technologies such as artificial intelligence (AI), machine learning, and the Internet of Things (IoT). These technologies are driving the next wave of automation, allowing machine tools to not only perform tasks autonomously but also learn and adapt to changing conditions. This evolution is paving the way for smarter, more efficient manufacturing processes that can meet the demands of a rapidly changing global market.

2. Key Technologies Driving Automation

The automation revolution in machine tools is being propelled by several cutting-edge technologies. At the forefront is AI, which enables machines to process vast amounts of data, recognize patterns, and make informed decisions. Machine learning, a subset of AI, allows machine tools to improve their performance over time by learning from past experiences.

The IoT is another critical technology, facilitating seamless communication between machines and systems. By connecting machine tools to a network, manufacturers can monitor performance in real-time, predict maintenance needs, and optimize processes for maximum efficiency. Additionally, advancements in robotics are enabling machine tools to perform tasks with unprecedented precision and speed, further enhancing their capabilities.

These technologies are not only increasing the efficiency of machine tools but also expanding their functionality. For instance, adaptive control systems can adjust machining parameters on-the-fly to optimize performance, while predictive analytics can anticipate problems before they occur, reducing downtime and increasing productivity.

3. Benefits of Machine Tool Automation

The automation of machine tools offers numerous benefits that are reshaping the manufacturing landscape. One of the most significant advantages is increased productivity. Automated machines can operate continuously with minimal supervision, significantly reducing production times and increasing output. This capability is particularly valuable in high-demand industries where speed and efficiency are critical.

Automation also enhances precision and quality. By minimizing human error, machine tools can produce components with exceptional accuracy and consistency. This precision is crucial in industries such as aerospace and automotive, where even the smallest deviations can have significant consequences.

Furthermore, automation reduces labor costs by minimizing the need for manual intervention. This reduction not only decreases expenses but also allows workers to focus on more strategic tasks, such as quality control and process optimization, ultimately leading to a more skilled and versatile workforce.

4. Challenges and Considerations

While the benefits of automation are undeniable, there are also challenges that manufacturers must address. One of the primary concerns is the initial investment required to implement automated systems. The cost of acquiring new technologies and training personnel can be substantial, posing a barrier for smaller manufacturers.

Additionally, the integration of advanced technologies requires careful planning and execution. Manufacturers must ensure that their systems are compatible and that data security is maintained to prevent unauthorized access and potential cyber threats. Moreover, as machine tools become more sophisticated, the need for skilled personnel to operate and maintain these systems becomes increasingly important.

Finally, there is the challenge of balancing automation with human labor. While automation can significantly enhance productivity, it also raises concerns about job displacement. Manufacturers must carefully consider how to integrate automation in a way that complements and enhances the workforce, rather than replacing it.

5. The Future of Machine Tool Automation

Looking ahead, the future of machine tool automation is incredibly promising. As technologies continue to advance, machine tools will become even more autonomous, intelligent, and capable. The integration of AI and machine learning will enable machines to optimize their own performance, reducing the need for human intervention even further.

Moreover, the development of new materials and manufacturing techniques, such as additive manufacturing, will expand the possibilities for machine tool automation. These advancements will open up new opportunities for customization and innovation, allowing manufacturers to create products that were previously unimaginable.

In the coming years, we can expect to see a greater emphasis on sustainability and energy efficiency in machine tool design. As concerns about environmental impact grow, manufacturers will increasingly seek to develop systems that minimize waste and reduce energy consumption, aligning with global sustainability goals.

Conclusion

The automation revolution in machine tools is transforming the manufacturing industry, offering unprecedented opportunities for efficiency, precision, and innovation. While challenges remain, the benefits of automation make it an essential component of modern manufacturing strategies. By embracing these technologies, manufacturers can stay competitive in an ever-evolving global market, shaping a future where machine tools are not just tools, but intelligent partners in production.

As we move forward, it is crucial for industry professionals to stay informed and adapt to these changes. By understanding the capabilities and potential of automated machine tools, manufacturers can position themselves at the forefront of this revolution, driving progress and creating a more efficient and sustainable future for all.