Data Future Creation Technology Fair: A Glimpse into the Future of Manufacturing

The Data Future Creation Technology Fair is an annual event that brings together the brightest minds and cutting-edge innovations from across the manufacturing industry. This fair is a beacon for professionals eager to explore the latest advancements in data-driven manufacturing technologies. As the industry continues to evolve at an unprecedented pace, this event serves as a critical platform for networking, knowledge exchange, and strategic planning for the future. In this article, we’ll delve into the highlights of the fair, covering key themes and innovations that are reshaping the manufacturing landscape.

Section 1: The Role of Data in Modern Manufacturing

Data has become the backbone of modern manufacturing, driving efficiencies and enabling more informed decision-making processes. At the Data Future Creation Technology Fair, numerous sessions highlighted how data analytics, machine learning, and artificial intelligence are transforming operations on the factory floor. Manufacturers are leveraging data to enhance product quality, optimize supply chains, and predict maintenance needs, ultimately leading to cost savings and increased productivity.

One of the standout presentations demonstrated the use of predictive analytics to foresee equipment failures before they occur. By analyzing historical data and monitoring real-time machine performance, companies can reduce downtime and extend the life of their equipment. This proactive approach not only lowers maintenance costs but also boosts overall efficiency and productivity.

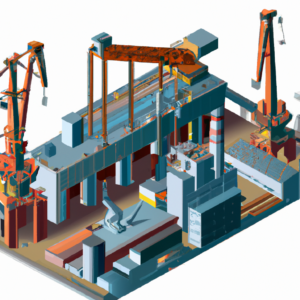

Section 2: Smart Factories and the Internet of Things (IoT)

The concept of smart factories was a central theme at the fair, with numerous exhibitors showcasing IoT-enabled devices and systems. IoT technology allows for the seamless integration of machines, sensors, and software, creating a fully connected manufacturing environment. This connectivity enables real-time data collection and analysis, fostering an agile and responsive production process.

Smart factory solutions presented at the event included automated quality control systems, which use IoT devices to monitor product specifications in real-time. This ensures that any deviation from the desired quality standards is immediately corrected, reducing waste and enhancing product reliability. Furthermore, IoT-driven inventory management systems were showcased, highlighting how they can streamline the supply chain by providing accurate, real-time inventory data.

Section 3: The Impact of Artificial Intelligence on Manufacturing

Artificial intelligence (AI) is revolutionizing the manufacturing industry by enabling smarter decision-making and automation. At the fair, several discussions focused on the integration of AI into manufacturing processes, highlighting its potential to improve efficiency and innovation. AI applications in manufacturing range from robotic automation to advanced data analytics, each offering unique advantages.

A key highlight was the presentation on AI-powered robotics, which are designed to perform complex tasks with precision and speed. These robots are equipped with machine learning capabilities, allowing them to adapt to changing environments and improve their performance over time. This adaptability can lead to significant improvements in production speed and quality, making AI an indispensable tool in the modern manufacturing toolkit.

Section 4: Cybersecurity in the Age of Connected Manufacturing

As manufacturing becomes increasingly interconnected, cybersecurity has emerged as a critical concern. The fair addressed this issue through seminars and workshops focused on protecting sensitive data and ensuring the integrity of industrial control systems. Participants were introduced to the latest cybersecurity strategies and technologies designed to safeguard manufacturing operations against cyber threats.

One of the key takeaways was the importance of adopting a comprehensive cybersecurity framework that encompasses everything from employee training to the implementation of advanced threat detection systems. By prioritizing cybersecurity, manufacturers can protect their intellectual property, maintain operational continuity, and build trust with customers and partners.

Section 5: Sustainability and the Future of Manufacturing

Sustainability is becoming a crucial consideration in manufacturing, and the fair highlighted numerous innovations aimed at reducing environmental impact. From energy-efficient machinery to sustainable supply chain practices, the industry is making strides towards a greener future. The fair provided a platform for discussing how data-driven technologies can support sustainability efforts.

One notable presentation showcased a data analytics platform designed to optimize energy usage across manufacturing facilities. By monitoring energy consumption patterns and identifying inefficiencies, manufacturers can significantly reduce their carbon footprint. Additionally, the fair highlighted the role of sustainable materials and circular economy practices in reducing waste and promoting resource efficiency.

Conclusion

The Data Future Creation Technology Fair serves as a vital forum for exploring the transformative impact of data-driven technologies on the manufacturing industry. From smart factories and AI to cybersecurity and sustainability, the fair covers a wide array of topics that are shaping the future of manufacturing. As manufacturers continue to embrace these innovations, they are poised to achieve unprecedented levels of efficiency, productivity, and environmental responsibility. By staying informed and connected through events like the Data Future Creation Technology Fair, manufacturing professionals can navigate the challenges and opportunities of this exciting new era.