Next-Gen Smart Factory Innovations

The manufacturing industry is undergoing a seismic shift as the integration of cutting-edge technologies transforms traditional factories into smart, interconnected ecosystems. These next-gen smart factories epitomize the pinnacle of efficiency, flexibility, and productivity, setting the stage for a new era in manufacturing. In this article, we delve into the latest innovations driving this transformation, exploring how they are reshaping the industrial landscape.

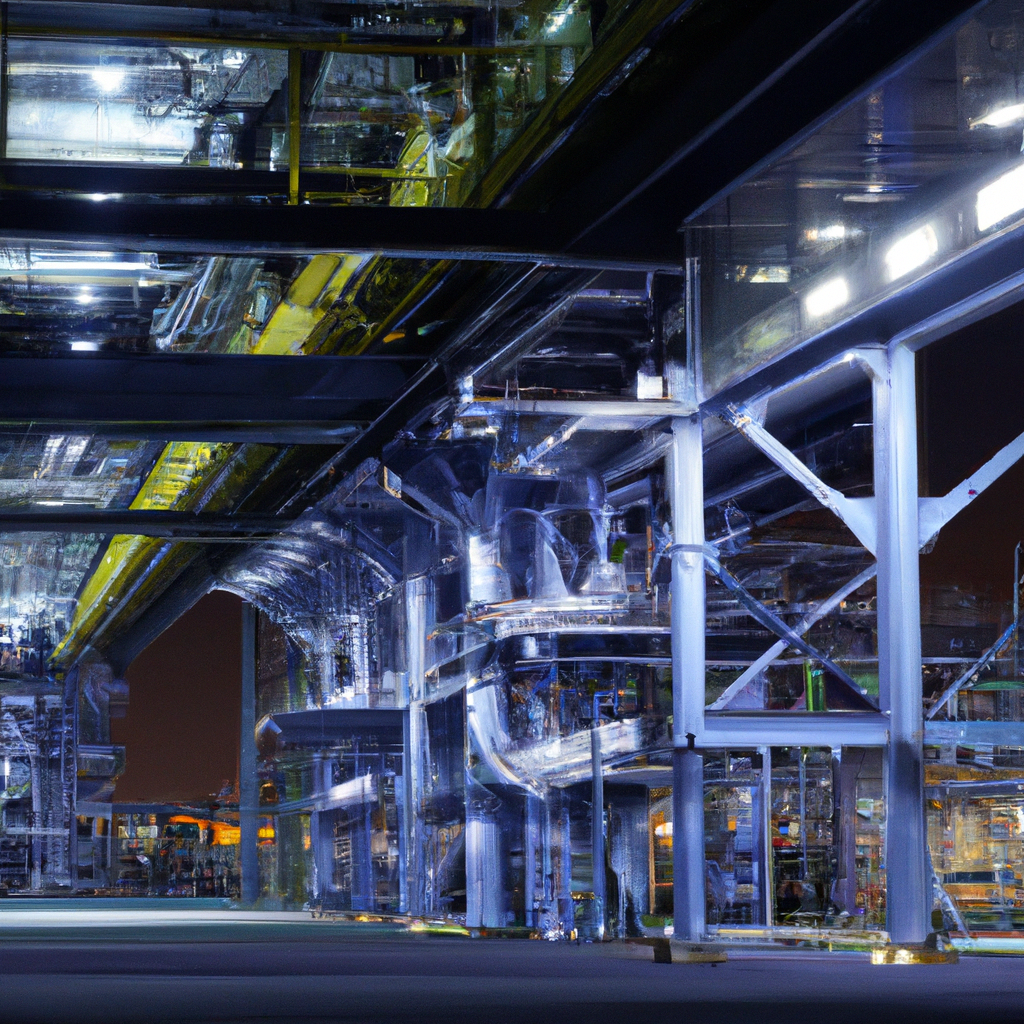

1. The Rise of the Industrial Internet of Things (IIoT)

The Industrial Internet of Things (IIoT) is revolutionizing manufacturing by embedding sensors and connectivity into machinery and equipment. This innovation facilitates real-time data collection and analysis, enabling manufacturers to optimize operations, reduce downtime, and enhance predictive maintenance.

By leveraging IIoT, factories can monitor everything from equipment health to energy consumption. This data-driven approach allows for proactive problem-solving, reducing the risk of unexpected breakdowns and extending the lifespan of machinery. Furthermore, IIoT facilitates seamless communication between devices, creating a cohesive network that enhances operational efficiency.

2. Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are at the forefront of smart factory innovations, driving automation and decision-making processes. AI-powered systems can analyze vast amounts of data to identify patterns and predict outcomes, enabling manufacturers to make informed decisions quickly.

Machine Learning algorithms, in particular, are instrumental in quality control. They can detect defects and anomalies in products with greater accuracy than human inspectors, ensuring that only products meeting the highest standards reach the market. Additionally, AI-driven robotics can adapt to new tasks effortlessly, increasing flexibility and reducing the need for extensive reprogramming.

3. Advanced Robotics and Automation

Robotic advancements have been a staple in manufacturing, but next-gen smart factories are taking robotics to new heights. Collaborative robots, or cobots, are designed to work alongside human workers, enhancing productivity and safety. These robots are equipped with advanced sensors and AI capabilities, allowing them to perform complex tasks with precision.

Automation extends beyond the assembly line, with robots now handling logistics, packaging, and even quality assurance. This holistic approach to automation improves efficiency across the entire manufacturing process, reducing costs and increasing throughput.

4. Digital Twins and Simulation

Digital twins are virtual replicas of physical assets, processes, or systems, allowing manufacturers to simulate and analyze operations in a risk-free environment. By creating a digital twin of a factory, manufacturers can experiment with different scenarios, optimize workflows, and identify potential bottlenecks before implementing changes in the real world.

This innovation is particularly valuable for predictive maintenance and lifecycle management. Digital twins provide insights into the future performance of machinery, allowing for precise maintenance scheduling and reducing the likelihood of unexpected failures.

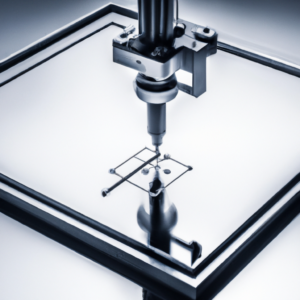

5. Additive Manufacturing and 3D Printing

Additive manufacturing, commonly known as 3D printing, is transforming the production landscape by enabling rapid prototyping and on-demand manufacturing. This technology allows for the creation of complex geometries that traditional manufacturing methods cannot achieve, opening new avenues for innovation.

In a smart factory setting, 3D printing can reduce lead times and minimize waste, as products are produced layer by layer, using only the necessary materials. This capability is particularly advantageous for industries requiring customization, as it allows for the production of tailored components with minimal setup time.

Conclusion

The evolution of smart factories represents a significant leap forward for the manufacturing industry. By embracing innovations such as IIoT, AI, advanced robotics, digital twins, and 3D printing, manufacturers can enhance their competitive edge, increase efficiency, and reduce costs. The integration of these technologies not only streamlines production but also fosters a culture of continuous improvement and adaptability.

As we look to the future, the potential for further advancements in smart factory technologies is immense. By staying at the forefront of these innovations, manufacturers can ensure they are well-positioned to meet the evolving demands of the global market, driving growth and success in the years to come.