Future Creation: Machine Tool Automation Expo

The rapidly evolving landscape of manufacturing is increasingly being shaped by innovations in machine tool automation. As industries strive for enhanced efficiency, precision, and productivity, the integration of advanced automation technologies into manufacturing processes has become paramount. The “Future Creation: Machine Tool Automation Expo” serves as a beacon for industry professionals, providing insights into the latest advancements and fostering discussions on the future trajectory of manufacturing automation.

Section 1: The Current State of Machine Tool Automation

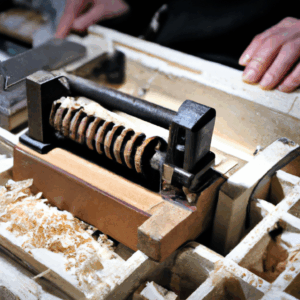

Over the past few decades, machine tool automation has transformed from a niche application to a core component of modern manufacturing. Automation technologies now encompass a wide range of systems, including CNC machines, robotic arms, and integrated software solutions, each designed to enhance production capabilities. The current state of machine tool automation is characterized by increased adoption of smart technologies, allowing for real-time data analysis and machine learning applications that optimize operations and minimize downtime.

Manufacturers are increasingly embracing automation to stay competitive in a global market. The integration of IoT (Internet of Things) devices in machine tools enables seamless connectivity and data exchange, providing valuable insights into operational efficiencies and potential areas for improvement. This connectivity is crucial as manufacturers aim to achieve the goals of Industry 4.0, where interconnected systems work harmoniously to streamline production processes.

Section 2: Key Innovations in Machine Tool Automation

The “Future Creation: Machine Tool Automation Expo” highlights several groundbreaking innovations that are set to redefine the manufacturing landscape. Among these is the advent of collaborative robots, or cobots, which are designed to work alongside human operators. Cobots enhance safety and efficiency by performing repetitive tasks, allowing human workers to focus on more complex and creative aspects of production.

Another significant innovation is the development of adaptive control systems that utilize artificial intelligence to adjust machining parameters in real-time. These systems enhance precision and reduce waste by automatically compensating for variables such as tool wear and material inconsistencies. Additionally, advancements in additive manufacturing, coupled with automated post-processing techniques, are expanding the possibilities for custom and on-demand production.

Smart maintenance technologies are also gaining traction, employing predictive analytics to foresee equipment failures before they occur. This proactive approach reduces downtime and maintenance costs, further contributing to the efficiency of automated manufacturing systems.

Section 3: Benefits of Machine Tool Automation

The benefits of machine tool automation are manifold, offering substantial improvements in productivity, quality, and operational costs. Automation reduces the dependency on manual labor, leading to consistent product quality and reduced human error. This reliability is crucial in industries where precision is paramount, such as aerospace and medical device manufacturing.

In addition to quality improvements, automation significantly boosts production speed. Automated systems can operate continuously without fatigue, maximizing throughput and allowing manufacturers to meet tight deadlines and adapt quickly to market demands. The implementation of machine tool automation also facilitates cost savings by minimizing waste and optimizing resource utilization.

Furthermore, automated systems provide manufacturers with enhanced flexibility, enabling them to quickly reconfigure production lines to accommodate new product designs or changes in demand. This adaptability is increasingly important in today’s fast-paced market environment, where consumer preferences and technological advancements rapidly evolve.

Section 4: Challenges in Implementing Machine Tool Automation

Despite the myriad benefits, implementing machine tool automation presents several challenges. One of the primary hurdles is the initial investment cost, which can be substantial. While the long-term savings and productivity gains often justify the expense, small and medium-sized enterprises may find it difficult to secure the necessary capital.

Another challenge is the integration of new automation technologies within existing systems. Manufacturers must ensure that new and legacy equipment can communicate effectively, which may require significant updates to IT infrastructure and software platforms. This integration process can be complex, demanding careful planning and execution to avoid disruptions in production.

Additionally, the shift towards automation necessitates a workforce with specialized skills. Manufacturers must invest in training programs to upskill their employees, ensuring they are equipped to operate and maintain advanced machinery. This transition can be challenging, particularly in regions with limited access to technical education and training resources.

Section 5: The Future of Machine Tool Automation

Looking ahead, the future of machine tool automation is poised to be transformative. As technologies continue to advance, we can expect further enhancements in machine intelligence, connectivity, and sustainability. The integration of artificial intelligence and machine learning will drive greater autonomy in manufacturing systems, enabling machines to make informed decisions and optimize processes with minimal human intervention.

Moreover, the continued development of digital twin technologies will revolutionize the way manufacturers design and test products. By creating virtual replicas of physical systems, manufacturers can simulate different scenarios and optimize processes before actual production begins, reducing time-to-market and increasing efficiency.

Sustainability is also becoming a focal point in the evolution of machine tool automation. Future systems will likely incorporate eco-friendly technologies that minimize environmental impact, such as energy-efficient machinery and waste-reduction strategies. These advancements will help manufacturers meet regulatory requirements and consumer expectations for sustainable production practices.

Conclusion

The “Future Creation: Machine Tool Automation Expo” is an essential event for manufacturing professionals seeking to stay at the forefront of industry advancements. As we explore the current state, innovations, benefits, challenges, and future prospects of machine tool automation, it is clear that this technology will continue to play a crucial role in shaping the future of manufacturing.

By embracing automation, manufacturers can achieve unprecedented levels of efficiency, quality, and flexibility, positioning themselves to thrive in an increasingly competitive global market. As the industry evolves, ongoing collaboration between technology developers, manufacturers, and policymakers will be vital in overcoming challenges and unlocking the full potential of machine tool automation.

Ultimately, the future of manufacturing is being forged today through the innovations and insights shared at events like the “Future Creation: Machine Tool Automation Expo,” setting the stage for a new era of industrial excellence.